Les ponts thermiques de liaison plancher et mur

Spécialiste de l’isolation, HIRSCH Isolation vous conseille sur les solutions à mettre en œuvre pour traiter ces ponts thermiques et garantir une enveloppe performante. Découvrez nos solutions pour un bâti durable et sain.

L’essentiel en 3 points

Au regard des déperditions globales d’un bâtiment, le traitement des ponts thermiques de liaison plancher / mur peut parfois sembler secondaire, c’est pourtant une opération rapide et simple qui, en plus d’être une obligation réglementaire, offre de nombreux bénéfices pour la pérennité du bâti, la performance thermique et le confort des habitants.

Ponts thermiques intégrés

Ponts thermiques de liaison

1. Qu’est-ce qu’un pont thermique ?

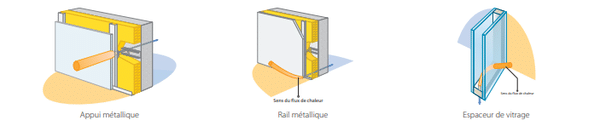

Un pont thermique est une discontinuité d’isolation provoquant une déperdition d’énergie. On en distingue deux grands types : les ponts thermiques intégrés et les ponts thermiques de liaisons.

Ponts thermiques intégrés

Les ponts thermiques intégrés sont créés dans une paroi par des éléments dont la conductivité thermique est plus élevée, par exemple un rail ou un appui métallique. Ils peuvent également être dus à un défaut de mise en œuvre ou d’assemblage provoquant un décalage entre les éléments isolants. Ces ponts thermiques ne sont pas à négliger car ils peuvent entraîner une forte augmentation des déperditions de la paroi, pouvant aller jusqu’à les multiplier par deux !

Ponts thermiques de liaisons

Les ponts thermiques de liaisons se retrouvent aux interfaces entre deux parois, typiquement entre une dalle et un mur, autour des encadrements de fenêtres ou au niveau des balcons. La déperdition thermique due à la discontinuité d’isolation entraîne un flux de chaleur du local chauffé vers l’extérieur ou vers un local non chauffé. On parle dans ce cas de pont thermique linéique. Cette valeur Ψ (psi) est exprimée en W / (m.K) et varie de 0 (absence de pont thermique) à 1,5.

Pourquoi traiter les ponts thermiques ?

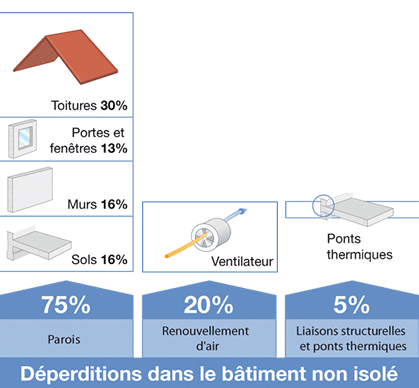

Une obligation réglementaire

Dans un bâtiment non isolé, la part des ponts thermiques dans les déperditions globales sera faible (environ 5%) car la perte de chaleur se fera principalement en partie courante des parois. En revanche, sur un bâti dont l’enveloppe sera fortement isolée, la part des déperditions dues aux ponts thermiques augmentera logiquement et pourra représenter entre 10 et 40% des déperditions totales selon la typologie de bâtiment.

Depuis la première réglementation thermique de 1974, face à une enveloppe de mieux en mieux isolée, la part des ponts thermiques dans les déperditions du bâtiment n’a donc cessé d’augmenter, jusqu’à la RT 2012. Cette dernière a intégré deux garde-fous relatifs au traitement des ponts thermiques pour les bâtiments neufs :

- Une valeur limite pour le Ψ entre le plancher intermédiaire et le mur extérieur de 0,6 W / (m.K).

- Une valeur limite globale de l’ensemble des ponts thermiques du bâtiment (relative à sa surface) fixée à 0,28 W / (m²SHON RT.K), qui permet une certaine flexibilité dans les choix constructifs en autorisant une compensation entre les différents ponts thermiques.

En définissant ces garde-fous tout en laissant le choix de la solution constructive au maître d’ouvrage, la RT 2012 a donc imposé le traitement des ponts thermiques et a été un véritable accélérateur dans leur traitement systématique sur les constructions neuves.

Depuis la première réglementation thermique de 1974, la part des ponts thermiques dans les déperditions du bâtiment n’a cessé d’augmenter.

Le non traitement des ponts thermiques des planchers intermédiaires peut entraîner une augmentation de la consommation d’énergie d’un bâtiment de 5 à 25%.

Un moyen de réduire la consommation énergétique

Réduire les déperditions d’énergie, oui, mais dans quel but ?

- L’énergie la moins chère étant celle que l’on ne consomme pas, réduire les déperditions va permettre de réduire les consommations d’énergie et donc d’alléger la facture énergétique pour les occupants du bâtiment.

Le non traitement des ponts thermiques des planchers intermédiaires peut entraîner une augmentation de la consommation d’énergie d’un bâtiment de 5 à 25%, selon les modes constructifs retenus et le type d’énergie employée. Cet impact sur les consommations d’énergie est également observable sur la performance environnementale et les émissions de gaz à effet de serre : la surconsommation due aux ponts thermiques non traités représente ainsi 11% des consommations dans l’Analyse du Cycle de Vie du bâtiment, ainsi que des Émissions de Gaz à Effet de Serre de 60 kgeqCO2/m² sur la durée d’exploitation de 50 ans.

- En maison individuelle, l’emploi de rupteurs de ponts thermiques va permettre de gagner environ 8 points de Cep – la consommation d’énergie primaire du bâtiment en kW par m² et par an, incluant le chauffage, la production d’eau chaude sanitaire, la climatisation, l’éclairage et les auxiliaires. Un gain non négligeable au regard du faible coût de ces produits et de leur simplicité de mise en œuvre.

Ne pas traiter les ponts thermiques dégrade donc sensiblement l’impact environnemental du bâtiment et augmente considérablement la consommation d’énergie et les émissions de gaz à effet de serre.

Une question de pérennité et de confort

Au-delà des questions de performance et d’économies, le traitement des ponts thermiques est crucial pour la pérennité du bâtiment sur toute sa durée de vie.

Prise en charge à la construction de l’ouvrage, dès les travaux de gros œuvre, cette opération va garantir un bâti performant à long terme. En effet, contrairement aux équipements qui peuvent être améliorés au fil du temps et des évolutions techniques, les ponts thermiques de liaison ne pourront pas être traités à posteriori : ne pas les traiter revient donc à laisser à plusieurs générations d’habitants un bâti déficient et source de pathologies.

L’une de ces pathologies est la formation de moisissures, qu’on retrouve le plus souvent aux jonctions des parois intérieures ou autour des menuiseries.

Dans ces zones, si le pont thermique n’a pas été traité, la température superficielle de la paroi peut être beaucoup plus basse que celle du local chauffé, créant une condensation qui peut entraîner l’apparition de moisissures. Ces dernières peuvent avoir des répercussions importantes sur la qualité de l’air intérieur et donc sur la santé des occupants.

Les sensations de sol froid (près des jonctions avec les murs), les parois froides ou les remontées d’humidité des vides sanitaires sont d’autres effets néfastes pour le confort des habitants qui peuvent survenir en cas de non traitement des ponts thermiques.

Apparition de moisissure aux angles des liaisons plancher mur en cas de discontinuité de l’isolation. Une zone froide se crée en surface et favorise l’apparition de condensation et, à terme, de moisissure.

L’isolation par l’extérieur est un moyen efficace de supprimer les ponts thermiques de liaison plancher/mur par l’ajout d’un isolant fixé ou collé sur la paroi.

3. Quelles solutions pour le traitement des ponts thermiques de liaison ?

Les modes de traitement vont varier selon le mode constructif choisi, les matériaux employés, le type d’isolation envisagé et la liaison considérée. Il n’existe donc pas de moyen standard de traiter un pont thermique, la réglementation laissant libre choix au maître d’ouvrage dans le choix de la solution appropriée.

Gamme Cellomur® : la solution pour l’isolation par l’extérieur

L’isolation par l’extérieur est un moyen efficace de supprimer les ponts thermiques de liaison plancher/mur par l’ajout d’un isolant fixé ou collé sur la paroi.

Cette technique a également l’avantage de pouvoir être mise en œuvre en neuf comme en rénovation.

La gamme Cellomur® offre une solution complète pour l’isolation des façades sous enduit mince. Les panneaux de polystyrène blanc ou graphité à hautes performances thermiques, collés ou chevillés au mur, présentent une stabilité dimensionnelle (pas de tassement dans le temps ni de rétractation de l’isolant), une planéité et une durabilité exceptionnelles.

Pour en savoir plus sur la gamme Cellomur® et l’offre Hirsch pour l’ITE, retrouvez notre guide pour l’isolation thermique par l’extérieur.

Isolation thermique par l’extérieur en rénovation de maison individuelle, avec des panneaux Cellomur® Ultra.

Le Système Epsilon® : rupteurs et accessoires pour planchers à poutrelles

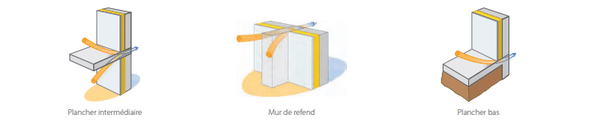

Les planchers à poutrelles sont le mode constructif de référence en maison individuelle, que ce soit sur vide sanitaire ou en plancher intermédiaire. Cette solution constructive présente, en cas d’isolation par l’intérieur, un pont thermique à la liaison de la dalle de compression avec le mur porteur, particulièrement en cas d’utilisation d’entrevous (ou hourdis) en béton. Un autre pont thermique se situe au niveau des murs de refend.

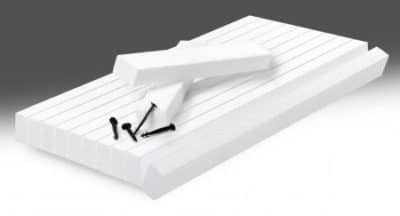

Le Système Epsilon® est une combinaison de hourdis isolants en polystyrène expansé et de rupteurs de ponts thermiques, permettant de réaliser l’isolation des planchers à poutrelles en partie courante et de traiter les déperditions linéiques à l’aide de rupteurs de ponts thermiques.

Plusieurs combinaisons de produits sont possibles, selon le plancher réalisé et le niveau d’isolation et de traitement des ponts thermiques souhaité :

- Les hourdis isolants Hourdissimo® ou Voutissimo®

Utilisés seuls, jouent le rôle de rupteurs partiels en réduisant l’épaisseur de béton de la dalle. Leur languette vient également recouvrir la sous-face des poutrelles pour traiter ce pont thermique intégré aux planchers.

- Les hourdis coffrants Hourdissimo® ou Voutissimo® Coffrant

Ils vont également servir de rupteurs partiels, sans assurer d’isolation en sous-faces des poutrelles. Par leur poids réduit et leur isolation en partie courante, ils remplacent avantageusement les hourdis béton pour la réalisation de planchers intermédiaires ou sous toiture-terrasse.

- Pour une performance maximale, on couplera ces entrevous avec des rupteurs Rupsilon® TLR , Rupsilon® PI ou Rupsilon® PI Protect. L’emploi de ces rupteurs permet un traitement des ponts thermiques efficace pour un coût et un temps de mise en œuvre réduits.

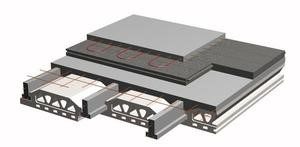

- Enfin, la solution la plus performante en termes de réduction des ponts thermiques de plancher est l’emploi d’un isolant sous chape complémentaire aux entrevous polystyrène : le plancher « Duo ».

Mise en œuvre après l’isolation des murs, l’isolation sous chape flottante à l’aide d’un panneau Solichape®, Maxisol®, Maxissimo®, Solissimo® Chauffant ou Solissimo® Silence va permettre de réduire le pont thermique linéique jusqu’à plus de 70%.

Pour en savoir plus sur le Système Epsilon®, retrouvez notre guide dans la Documentation.

Isolation du mur de refend de plancher avec le panneau Rupsilon® TLR et l’attache Omega.

Isolation d’un plancher à poutrelles précontraintes avec les entrevous Voutissimo®.

Plancher Duo avec entrevous isolants et isolation complémentaire sous chape.

Focus sur les rupteurs

de ponts thermiques

Les rupteurs de ponts thermiques sont des éléments isolants permettant de traiter les liaisons entre les parois d’un bâtiment. Placés en about d’une dalle, ils assurent la continuité de l’isolation par l’intérieur et réduisent les déperditions.

En plus de leur rôle thermique, les rupteurs doivent garantir la stabilité structurelle des ouvrages dans lesquels ils sont intégrés – notamment dans les zones à risque sismique – ainsi que la tenue au feu de ces ouvrages. Ils ont également un rôle acoustique dans la transmission du bruit entre locaux.

Les systèmes de rupteurs disponibles sur le marché doivent bénéficier d’un Avis Technique du CSTB. Le système HIRSCH Isolation est couvert par l’ATEc n° 3.1/16-888

Rupteur de ponts thermiques Rupsilon® PI.

PRODUITS ASSOCIÉS

-

Hourdissimo® T 600

Entrevous isolant découpé, pour montage sur poutrelles treillis à talon de 40 à 45 mm de hauteur, en entraxe 600...

-

Rupsilon® PI L

Rupteur de pont thermique moulé pour le traitement des rives longitudinales de plancher.

-

Rupsilon® PI T

Rupteur de pont thermique moulé pour le traitement des rives transversales de plancher.

-

Rupsilon® TLR

Rupteur de ponts thermiques 3 en 1 pour le traitement des rives longitudinales, transversales et du mur de refend de vide...